whaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaat???

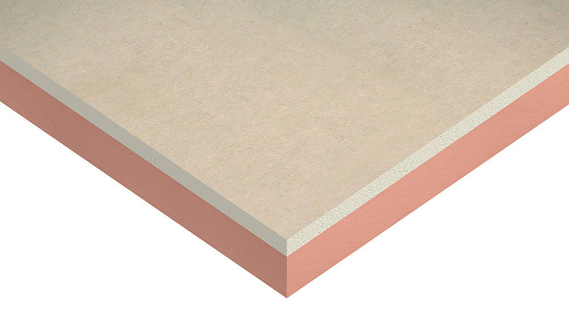

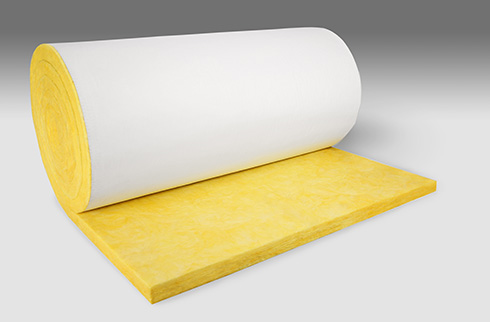

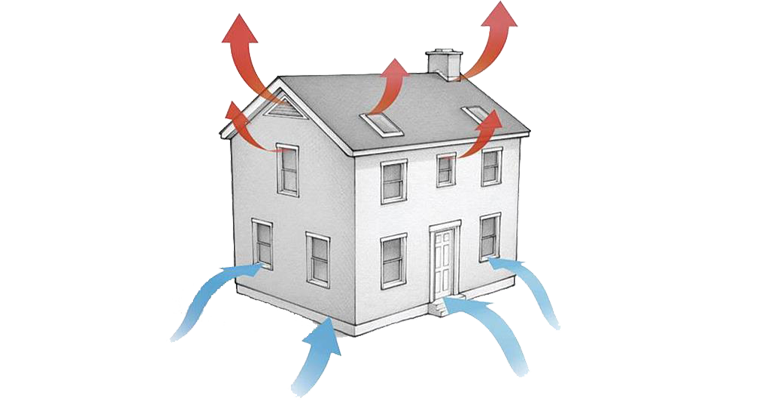

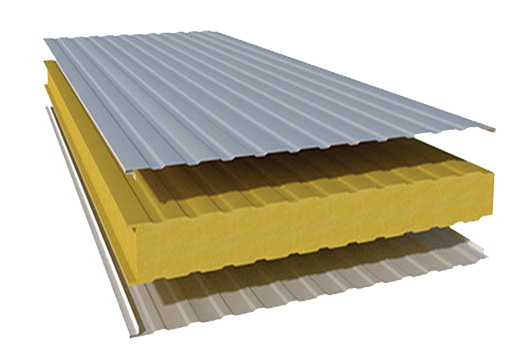

all this babble about different ways to insulate

and then a youtube video tutorial from some people insulating a shipping container home -that had never done it before …

I thought this was from someone that had experience doing it

nice to see different types of insulation -thanks for that 🙂

but I`m still confused

conclusion: here are different types of insulation -still don`t know what to use

and it should be noted about spray foam insulation that it can be incredibly toxic -even after it is applied and can cause a lot of severe health issues -scary stuff

I do not even know how I ended up here, but I believed this put up was once great.

I don’t realize who you’re but certainly you’re

going to a well-known blogger in the event you are not already.

Cheers!

My colleagu will get back to you later